The world's cheapest metal laser cutting machine

Maximum cutting thickness(Need oxygen assist)

Maximum cutting thickness(Need oxygen assist)

Product Description

1.CE/FDA/ISO certification

2.imported precise linear guide rial system

3. Control system ruida-6442g

4. 57mm Just motion stepper motor diver and stepper motor

5. electric lifting table 0-50cm automatic lifting system

6. trademark laser tube

7. high end customized industrial synchronous belt

8. Should be able to auto feed. (optional)

9.front back material feeding device,the material can go through the machine front &back (optional)

| working Area | 1300 *2500mm |

| Laser Type | CO2 glass Laser Tube |

| Control system | RuiDa off line |

| Laser tube | 200w /300w/450w |

| Cutting Speed | 0-1000mm/s |

| lift platform | Electric adjust up and down 0-500mm |

| Minimum Shaping Character | 1 *1mm / (0.04 *0.04)in |

| Engraving focus | Automatically find focus |

| Engraving positioning | Red light positioning |

| Power Supply | AC220V± 50HZor110V±10%60HZ |

| Guide | linear guide (PMI) |

| Resetting Positioning Accuracy | Accuracy less than or equal to 0.01mm 0.0004in. |

| Software supported | Lasercut 5.3(Included) PLT, DST, DXF,DWG.CDR, AI, Auto CAD, Coreldraw |

| Maximum lifting height of platform | 270mm/10.63in.(Up and down adjustable by motor) |

| Laser Tube(Life time) | 8000-10000Hours |

| Driving system | 57mm Just motion stepper motor diver and stepper motor |

| Stepper Motor | Just motion control |

Mixed Carbon Steel Laser Cutting Machine

- Adopt Advanced Germany Mix Cutting Technology

- It supports both Metal and Non-Metal Cutting, can cut stainless steel, carbon steel, mild steel, also can cut acrylic, wood, MDF engraving and cutting.

- Advanced Laser Optical System

- Ensure Excellent Laser Beam Quality,can strongly improve the laser power and laser beam quality.

- Laser Path Pre-view & Pre-position Function

- Laser beam is in-visible,by adopting “Red Light Pointer” ,Realize the laser path pre-view and Pre-position function.

- Unique Mirrors and Lens Cooling Technology

- All mirrors and lens is cooled by water ,Takes the mirror heat during working,Prolong its’ lifetime ,Save future operation cost

- Dynamic Auto-focus Metal Sheet Laser Cutting Head:

- When the metal sheet is not plain, the dynamic focus laser cutting head can adjust the focusing distance automatically.

- Realize the accuracy of cutting effect.

- Advanced Colorful LCD Screen+ USB Port+ DSP Offline Control

- Support Both Metal and Non-Metal,Cutting Parameters,Support U disk, USB communication.

- Thicken Strip Working Table Specially Used for Cutting

- Meets the need of diversified laser procession,Heavy Loading,Suitable for cutting heavy and hard products

- Adopt Belt Transmission+Chinese Top Brand “Leadshine” Step Motor and Driving System configuration which has high cost performance

Metal cutting parameters

Auto-focus Metal Sheet Laser Cutting Head

When the metal sheet is not plain, the dynamic focus laser cutting head can adjust the focusing distance automatically.Realize the accuracy of cutting effect.

Control panel

3.5" display screen;

Off line operation, 128M storage;

Visable dynamical processing track;

Graphic online preview.

Support multiple file formats;

Support lightburn software

Laser source display

| Material | thickness(mm) | Maximum power of CO2 laser tubew | Maximum cutting power% | speed (mm/s) | Air pressure(MPa) |

| Stainless Steel | 0.8 | 150 | 65 | 40 | 0.6 |

| 1 | 260 | 65 | 30 | 1 | |

| 2 | 260 | 65 | 20 | 1.2 | |

| 3 | 260 | 80 | 20 | 0.6 | |

| 1 | 280 | 45 | 30 | 0.5 | |

| 1.2 | 150 | 70 | 30 | 0.6 | |

| 1.5 | 150 | 60 | 15 | 0.8 | |

| Carbon Steel | 1 | 280 | 55 | 20 | 0.5 |

| 2.5 | 260 | 65 | 10 | 1.2 | |

| 3 | 260 | 80 | 20 | 1 | |

| 1.8 | 150 | 70 | 30 | 1.3 | |

| Galvanized Sheet | 2 | 260 | 65 | 10 | 1.1 |

| 2 | 150 | 70 | 20 | 0.8 |

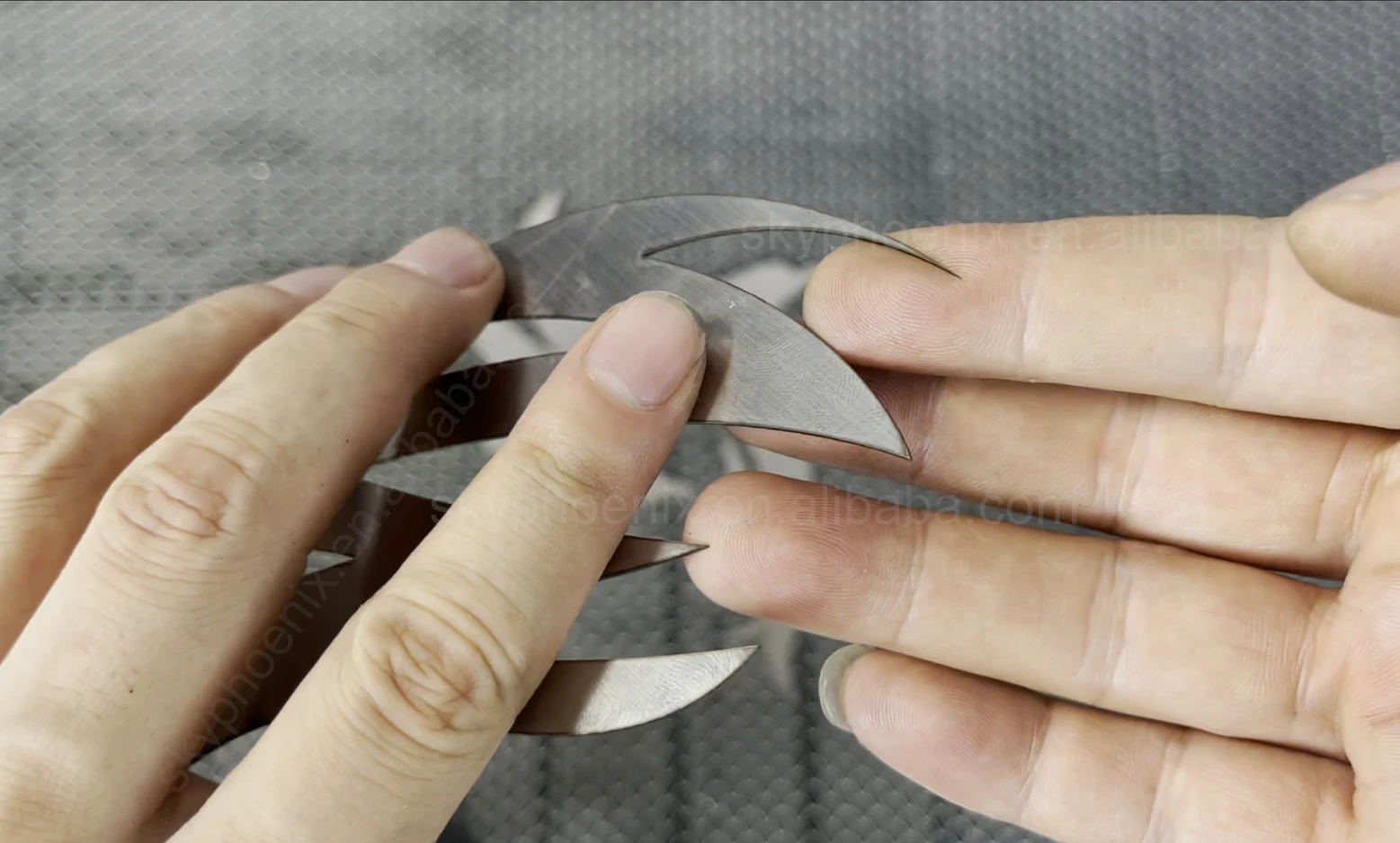

Cutting stainless steel and carbon steel samples

Note:

Mixing machine assembly workshop

Buying Guide

For mix cuttinng laser machine we supply dozens of models and we can also customized the machine based on your special demand , pls kindly offer below info before inquiry :

1. What materials you want to process? (Stainless Steel, carbon steel ….)

2. What is the mostly used thickness and what is the maximum thickness? (0.5mm,1mm,2mm….)

3. What is the max dimension of your sheet metal? (1500 x 3000mm, 1300*2500mm….)

4. What will be the metal used for after processing? (Such as Electrical boxes, advertisement …)

5. Are you an end user or reseller?

Related products

-

Cutting-Machine-for-metal-and-nonmetal

1390 CNC Laser Mixed Cutting Machine

Rated 0 out of 5$8,900.00 Add to basket

Reviews

There are no reviews yet.